MSE research ream, led by Prof. Jiajie Liang, reported a new method to lower internal friction of 0D–1D–2D ternary nanocomposite‐based strain sensor by fullerene to boost the sensing performance.

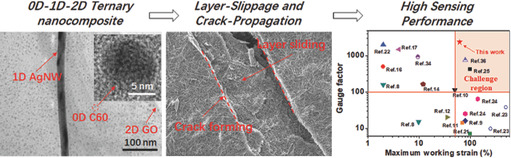

The development of strain sensors with both large strain range (>50%) and high gauge factor (>100) is a grand challenge. High sensitivity requires material to perform considerable structural deformation under tiny strain, whereas high stretchability demands structural connection or morphological integrity for materials upon large deformation, yet both features are hard to be achieved in one thin film. A new 0D–1D–2D ternary nanocomposite–based strain sensor is developed that possesses high sensitivity in broad working strain range (gauge factor 2392.9 at 62%), low hysteresis, good linearity, and long‐term durability. The skin‐mountable strain sensor, fabricated through one‐step screen‐printing process, is made of 1D silver nanowire offering high electrical conductivity, 2D graphene oxide offering brittle layered structure, and 0D fullerene offering lubricity. The fullerene constitutes a critical component that lowers the friction between graphene oxide–based layers and facilitates the sliding between adjacent layers without hurting the brittle nature of the nanocomposite film. When stretching, layer slippage induced by fullerene can accommodate partial applied stress and boost the strain, while cracks originating and propagating in the brittle nanocomposite film ensure large resistance change over the whole working strain range. Such high comprehensive performance renders the strain sensor applicable to full‐spectrum human motion detection.

The work was published by Advanced Functional Materials. DOI